As promised, I’m back to let you know what’s been happening with The Fire Bike, my V7 loopframe.

An MPH speedometer that works.

Around here it’s important to have an accurate speedometer. Fixed speed cameras, mobile camera vans and other gizmos are there to lighten our wallets if we get it wrong. This bike, being an import to the UK, came with a KPH only speedometer. This is perfectly legal on a bike built before 1986. It has to have a speedo but there are no rules about it showing miles per hour. Trouble is that all our signs and speed limits are posted in MPH. A while back, to avoid having to make calculations in my head, I stuck bits of Dymo tape on the speedometer glass to show speeds up to 70MPH which is the highest of the national speeds limit here.

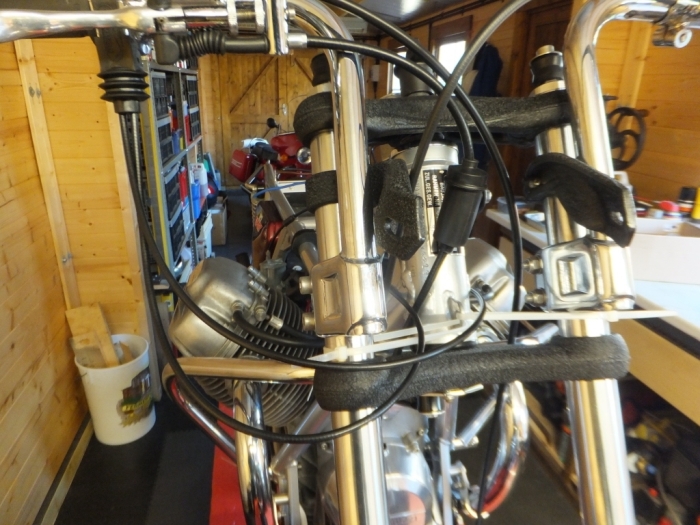

However I’ve noticed that the speedometer reads well over the actual speed I’m doing. I know all vehicles read high but, in this case, it really is well over. Locally, there are some signs which flash up your speed as you approach them. They would show 24 when I was riding at 30. My answer was to fit a bicycle speedometer. It cost me all of £5 and I made a bracket to fit it in the fairing in such a way that it can’t be slid off its mount.

The sender normally would get its signal from a magnet attached to a spoke but, this won’t work here as the spokes are too chunky and the magnet would be much too far away from the pick-up. My solution was to buy some cheap magnets off ebay and to stick one to the rim with “Stixall”, a silicone adhesive. It was positioned opposite the valve hole to help balance it. A bracket was made to mount the pick-up to the mudguard mounting screws on the right hand fork leg.

The bicycle speedometer is self contained with its own battery and goes to sleep when not used for a few minutes. It wakes itself up when the wheel movement triggers the sensor. It was calibrated by marking the tyre sidewall, rolling the bike forward one wheel revolution, measuring the distance traveled and inputting this figure as per the instructions. There are a lot of other redundant functions but the clock is handy. You can also set a trip milometer but I shan’t bother.

It has been a success. The reading is accurate, reading just 1MPH over when showing 40 i.e. I’m doing 39MPH. You can’t read it at night but never mind. The magnet has, much to my surprise, stayed well and truly stuck to the wheel as well.

Cheap topbox.

I have a couple of old but sound 36 litre Givi cases but nothing to mount them to. You’re talking about £45 for a universal mounting plate which isn’t too bad but, my boxes are still too small to put a helmet in when I leave the bike. I also need more space for camping gear because the bike’s panniers are so small. I found I could get a cheap Chinese made 46 litre top box with quick-release mounting plate for £40 so got one of those. It’s definitely not made anywhere near as as well as a Givi box but was less than a quarter of the price. I mounted the universal plate to my chrome rack.

Then fitted what is a pretty massive box.

I know it looks a bit out of place but it’s functional and feels secure on its mounting. I only fit it as needed and have used it empty as somewhere to put my helmet or jacket (helmet then ends up secured with a cable lock as before). I also used it to carry camping gear for the V-twin rally in August. That time, I also strapped the box to the rack as a belt-and-braces measure. I could just shove a bolt through box and rack but, the design of the original panniers means the box has to come off to get them fully open. They can still be partially opened with the box on and you can just about fish around for stuff.

I’ll consider fitting lights to the box because it overhangs the existing ones. If you’re sat in a car behind the bike, the lights are visible but they might be hidden from someone sitting in a higher position and closer behind.

MOT test time.

In the UK the MOT is the annual road-worthiness test. Toward the end of September I took The Fire Bike to my usual tester who was as thorough as always. The bike passed easily with no advisory notices. He agreed with me that there is the slightest bit of play in the rear wheel bearings but, wasn’t concerned.

I was interested to see how the bike would fare on the brake testing rollers. With the tester sat on the bike each wheel is weighed. Each brake is applied incrementally to ensure it works progressively, doesn’t grab or stick on. It’s then fully applied to test its efficiency. Apparently the front of the bike weighs about the same as a modern sports tourer. The braking efficiency of the front twin leading shoe drum brake is also on a par with a modern disk set up. The downside is that brake fade is more likely from a drum than disks which are able to shed the heat more easily. The rear end of the bike is some 25Kg heavier than a modern sports bike. The efficiency of the rear single leading/single trailing drum brake is close to the efficiency standard of disk brake with the same caveat about brake fade.

Having got my MOT pass I was able to go home and tax the bike for another year. This is compulsory but free as the bike is registered as an historic vehicle due to its age.